Installations

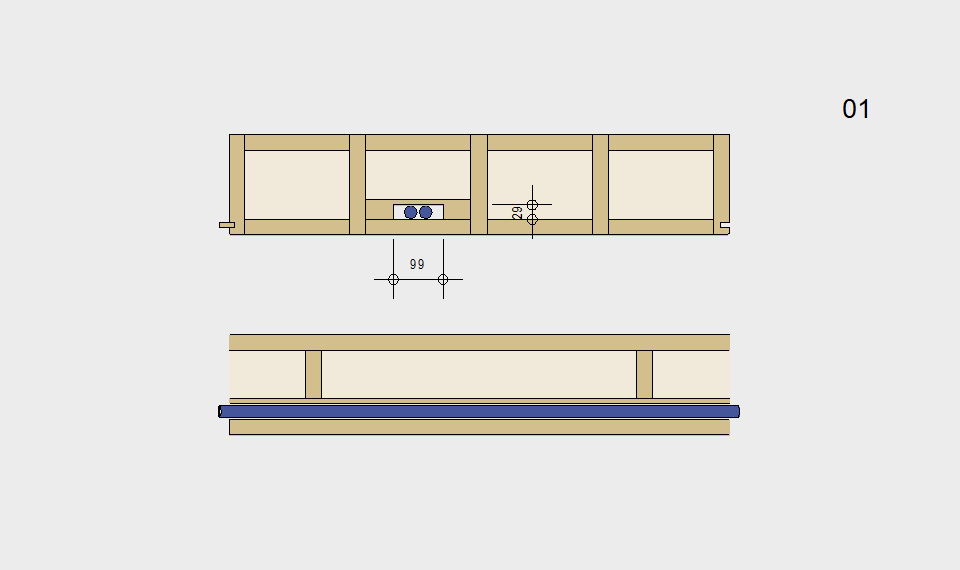

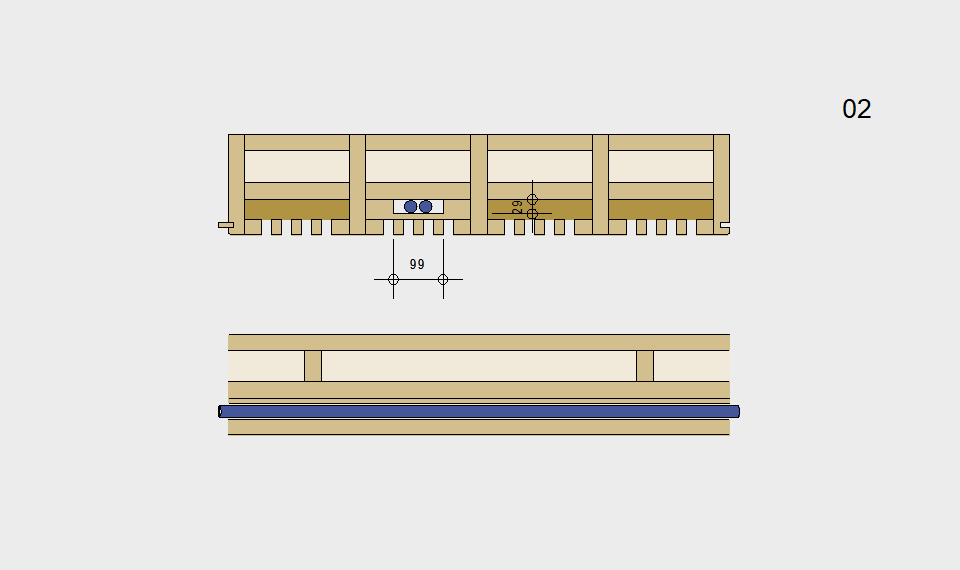

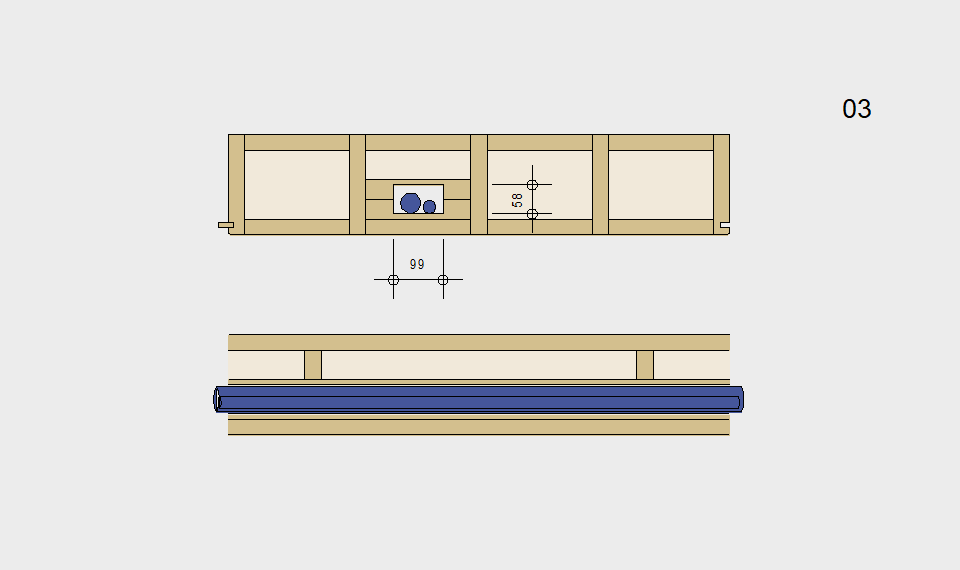

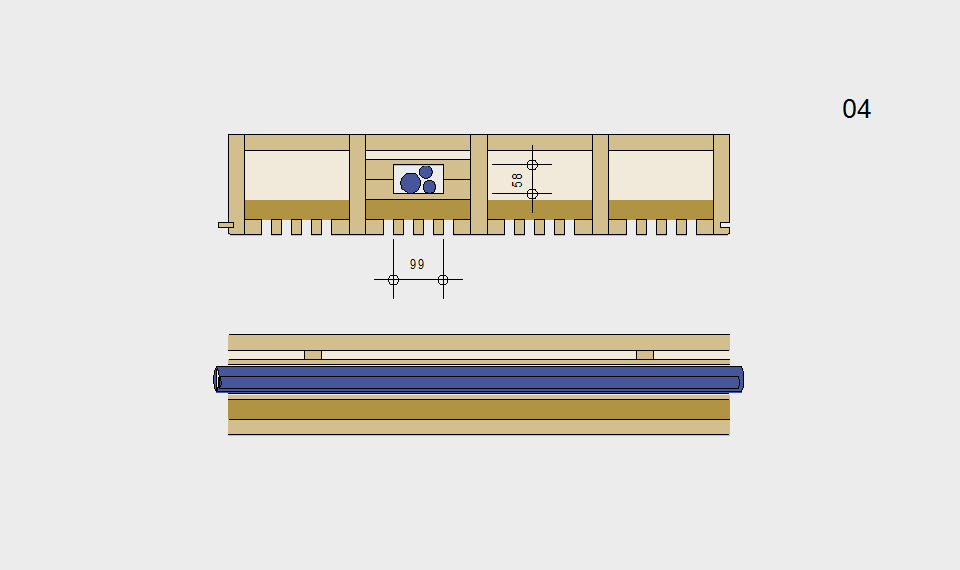

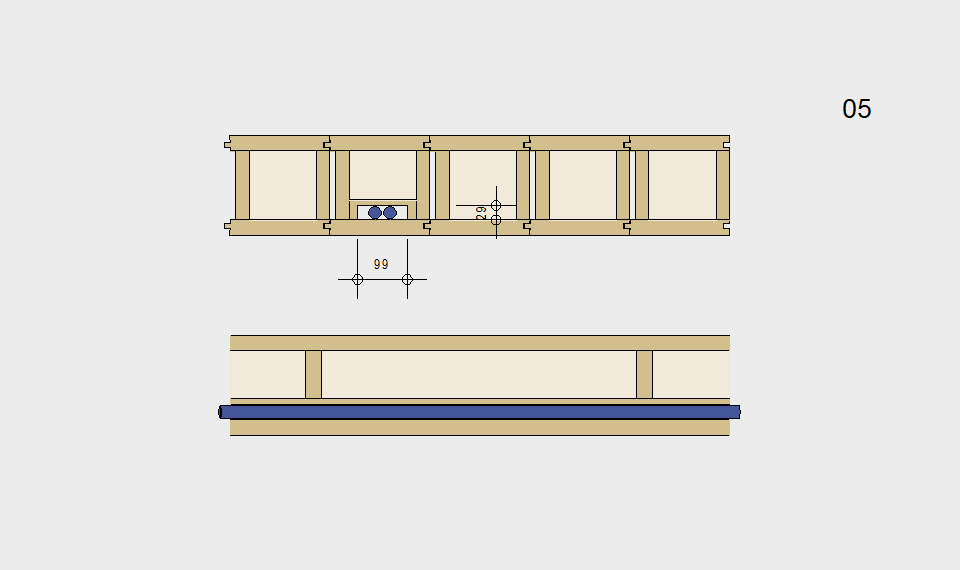

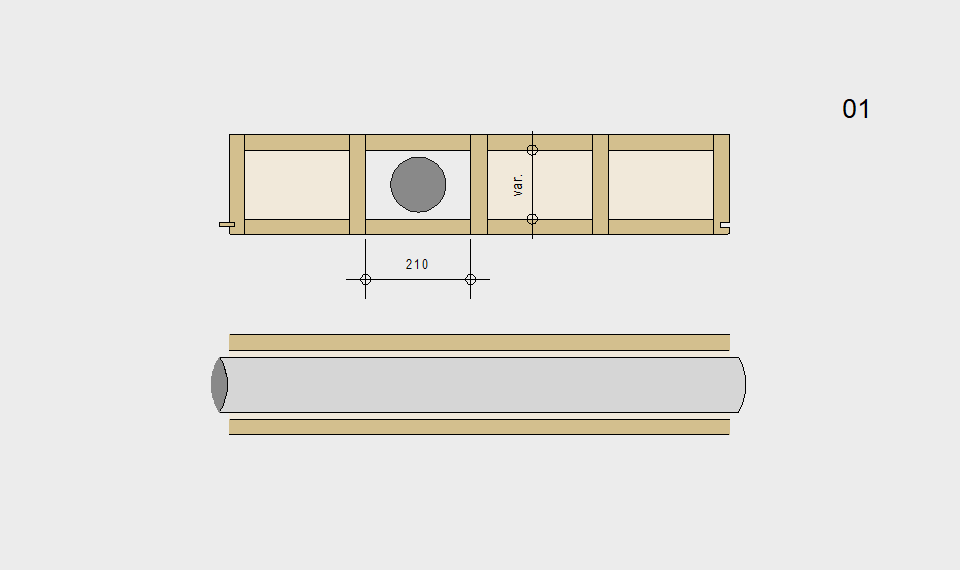

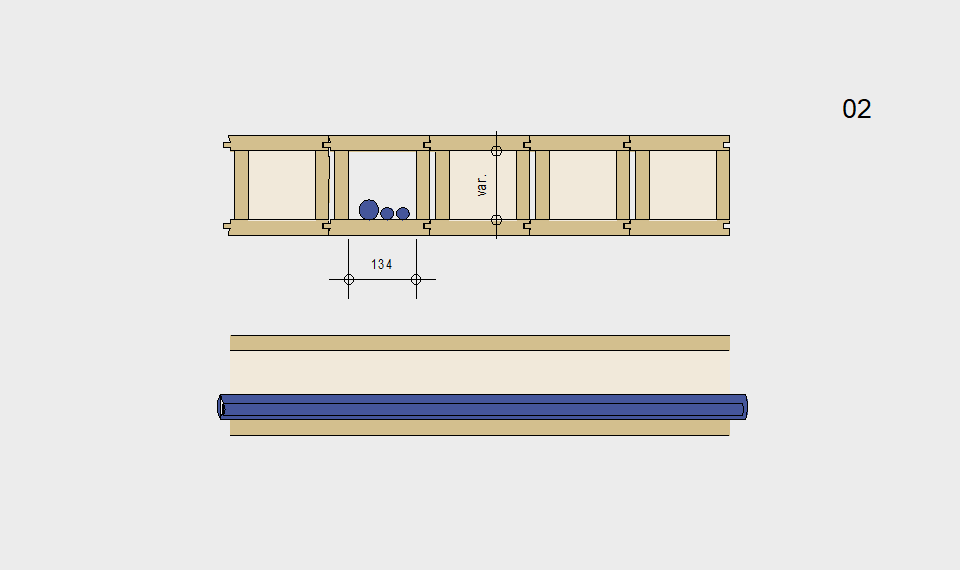

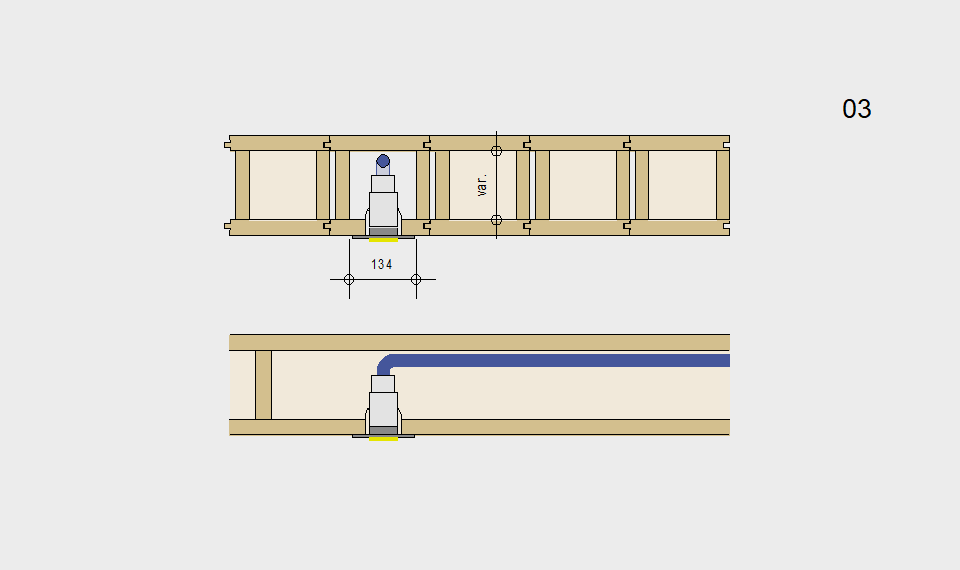

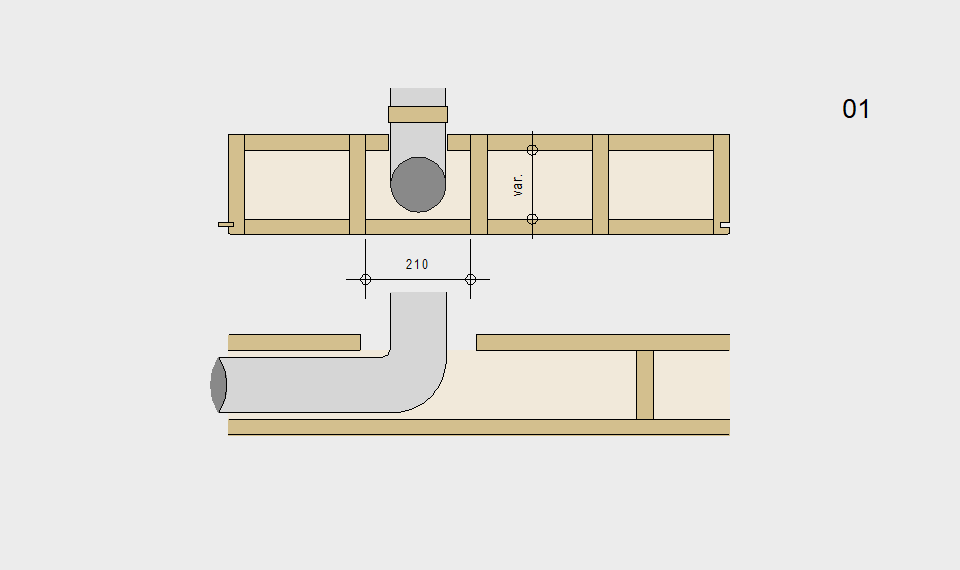

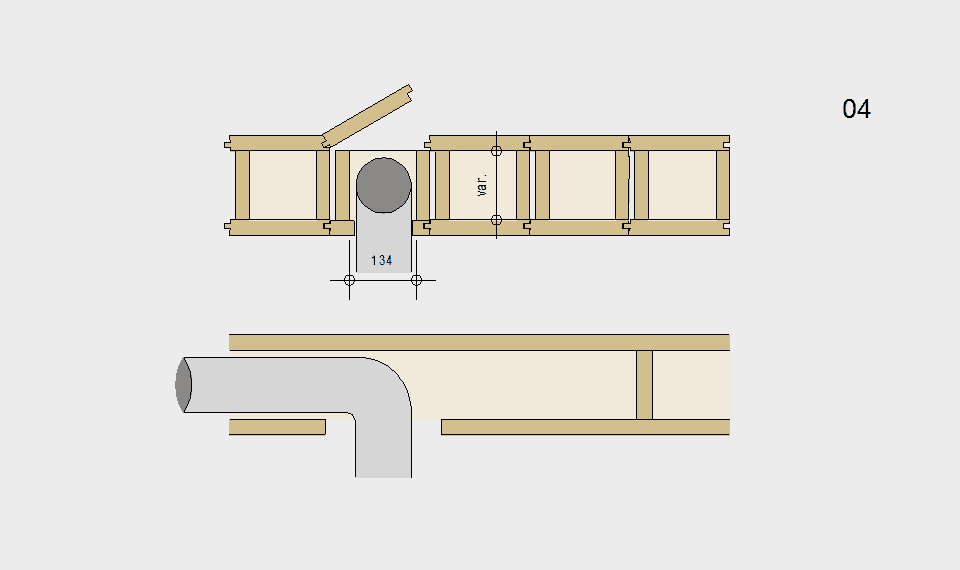

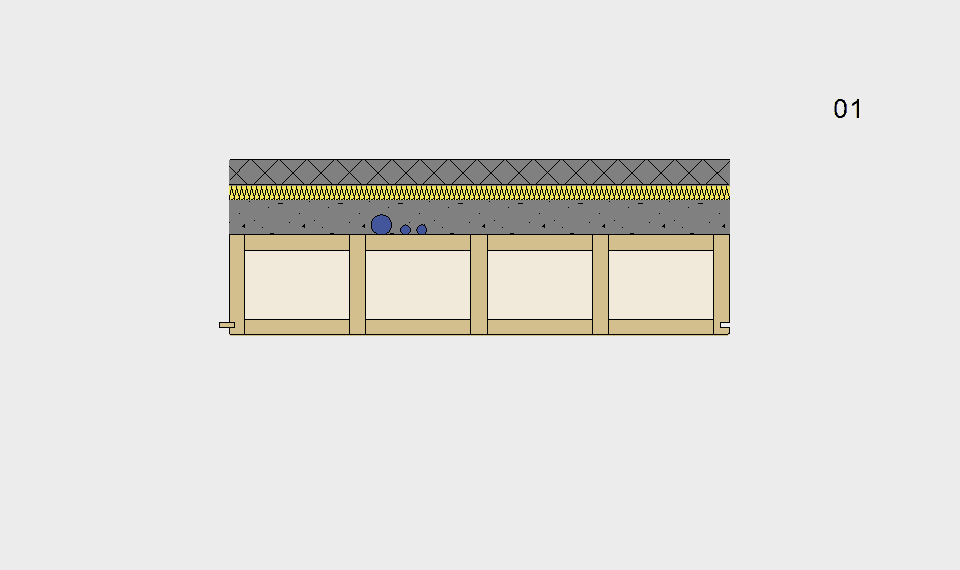

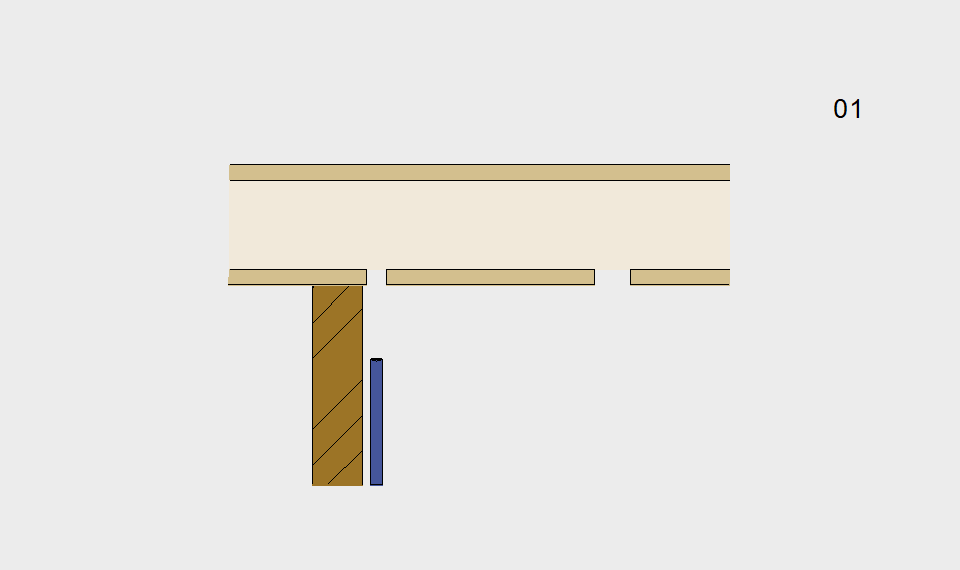

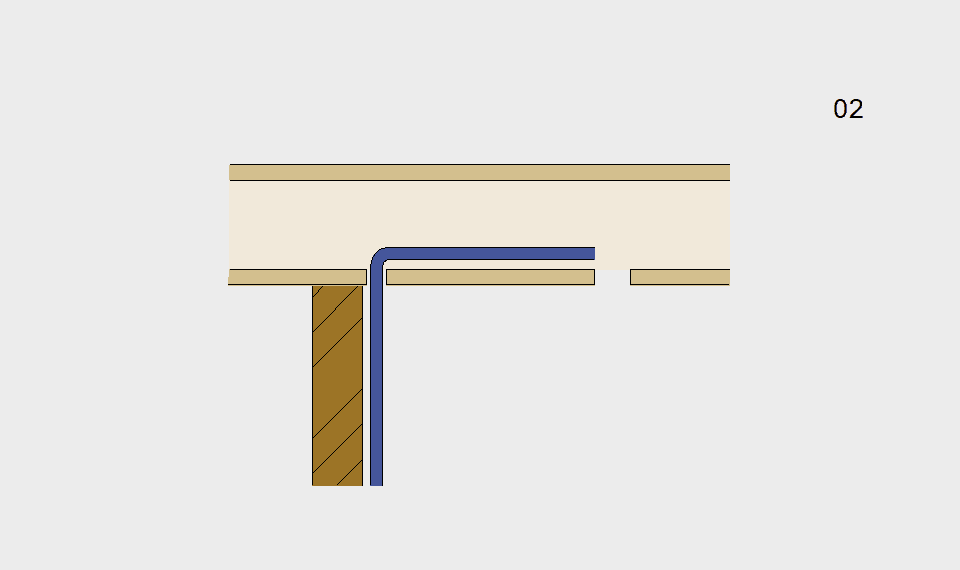

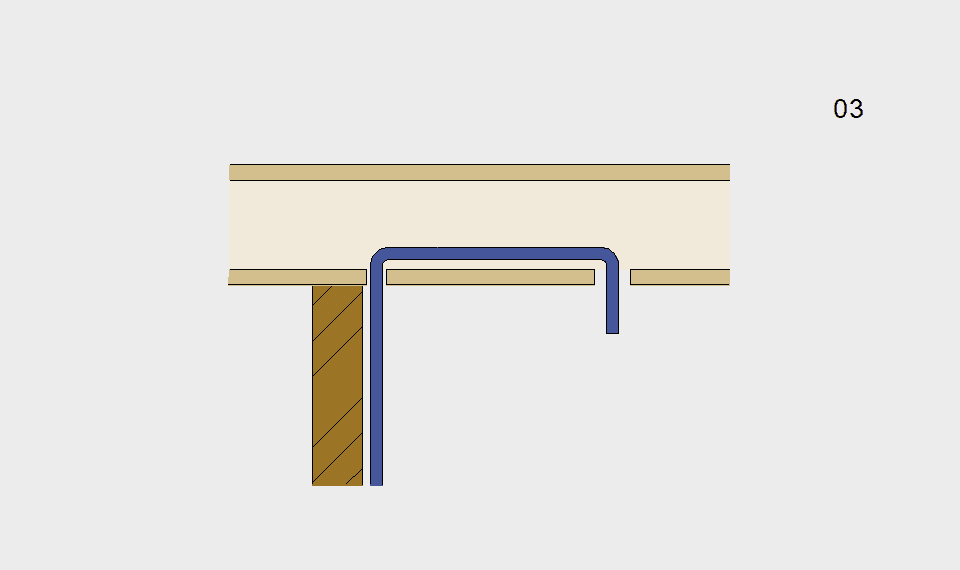

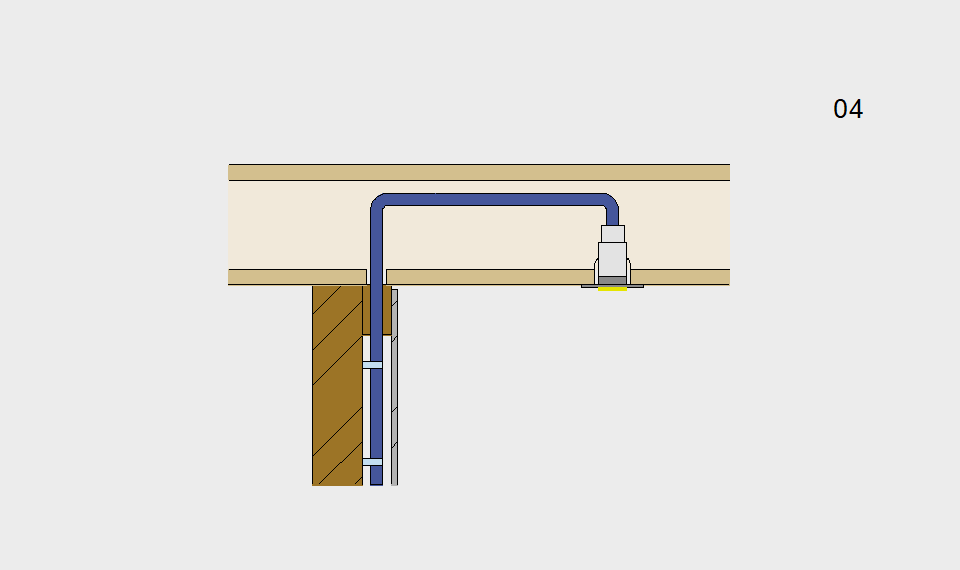

The cavities of the LIGNATUR elements are partitioned at regular intervals and cannot be used for service channels without further measures. On order we are happy to prepare the elements for your services. With the box element, we can put back the web, remove the cross webs or cut grooves locally with the trimming line. With the surface element, we can reposition the upper slat to the bottom. We also offer a special slat for installations.

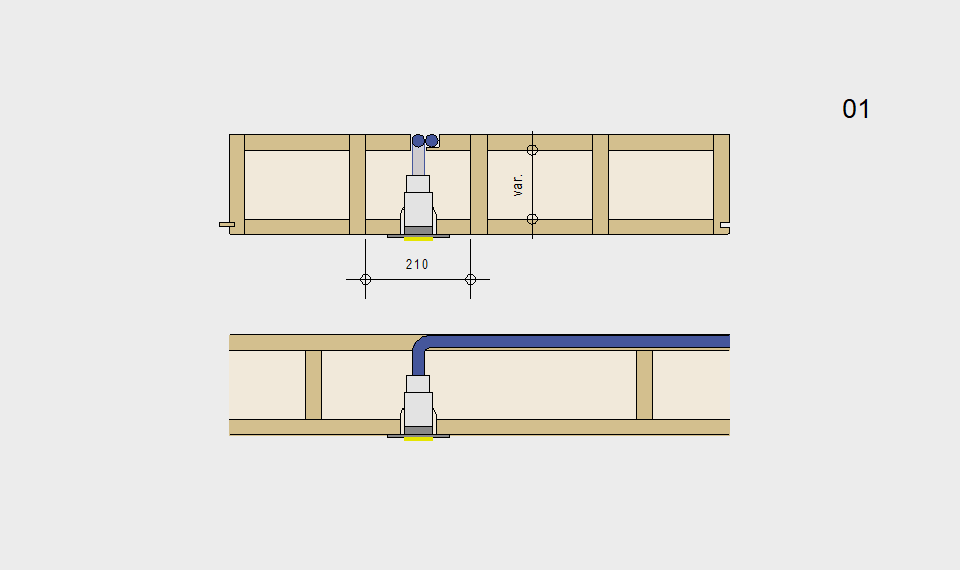

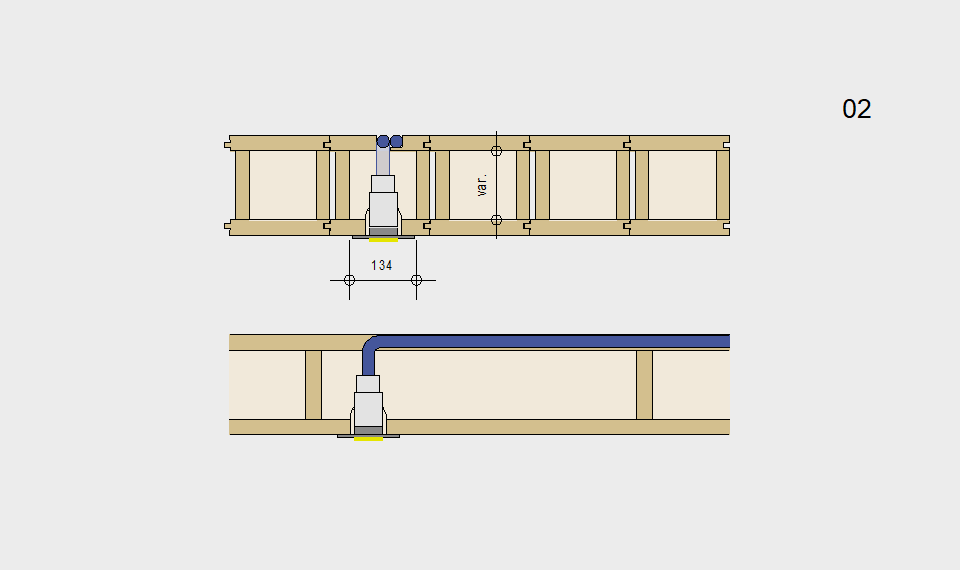

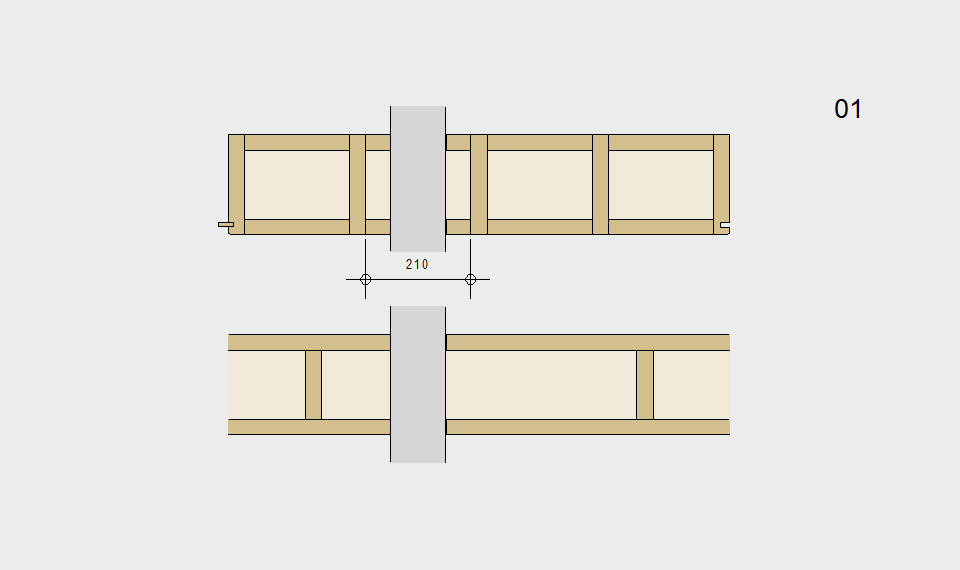

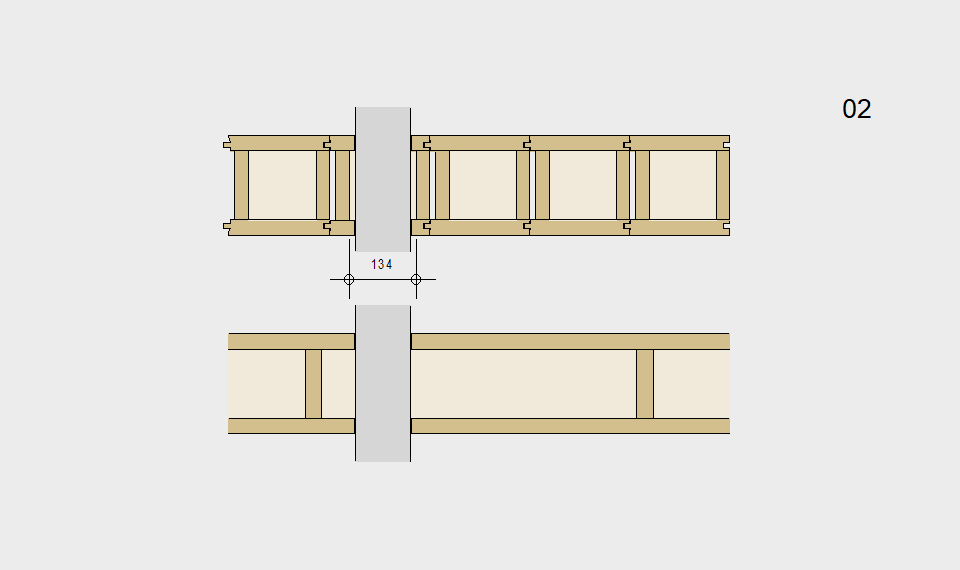

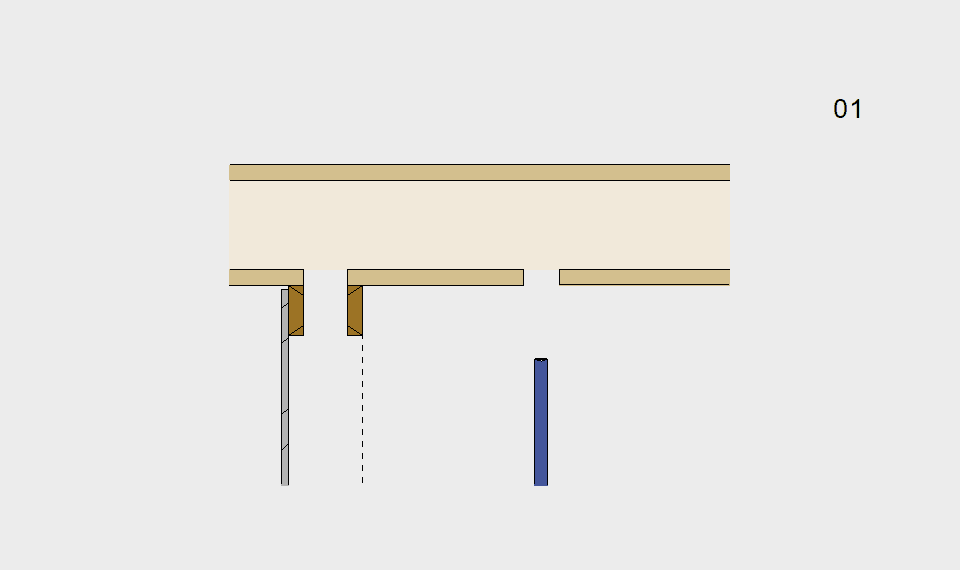

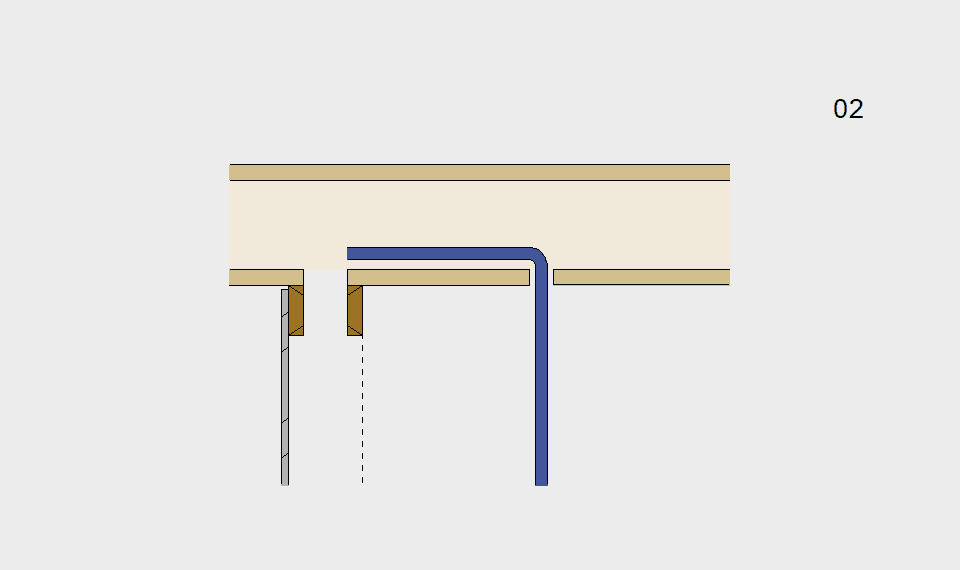

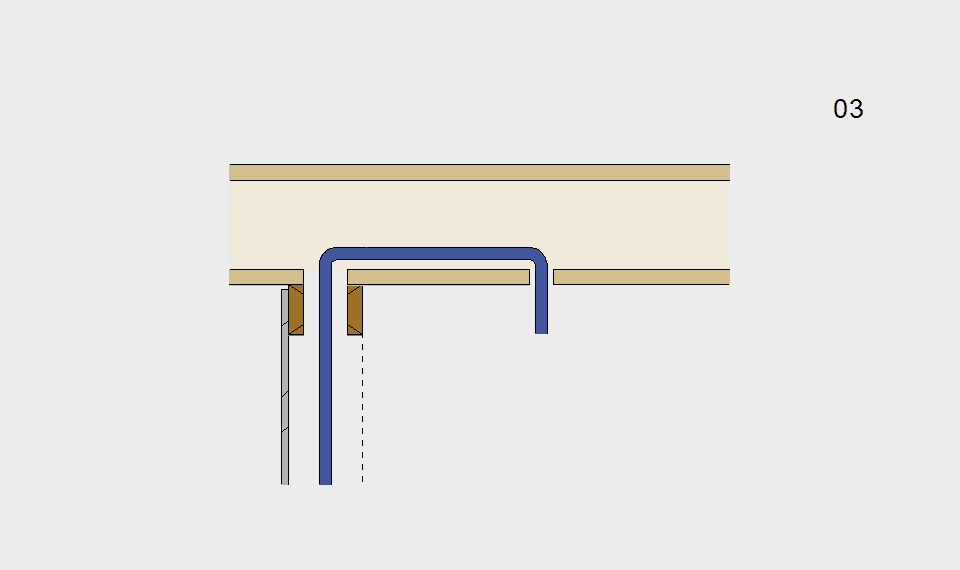

Single vertical penetrations are possible without structural reinforcement in the area of the cavity, with the box element up to 130mm and with the surface element up to 200mm.

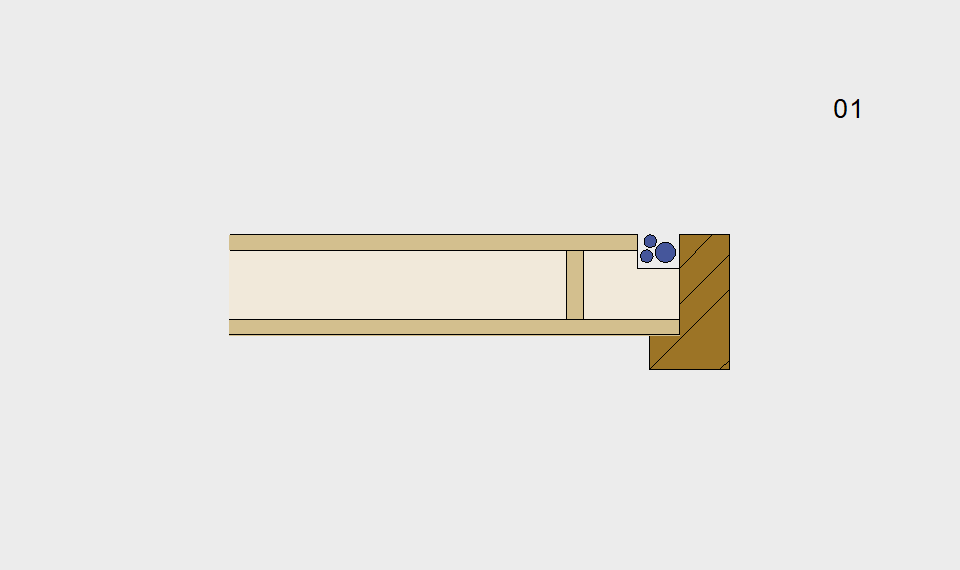

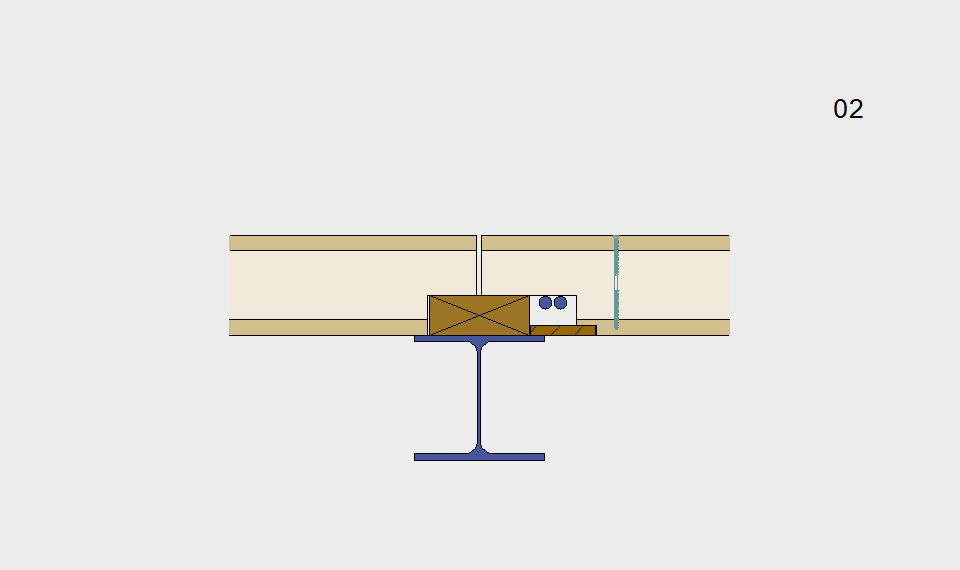

The cross distribution is easiest if done in the zone of the bearing. Of course, services can also be installed in a sound insulation layer or in bonded chippings and the underfloor heating be put in the screed.